Free shipping on most purchases over $150! (see conditions and exceptions at bottom of home page)

West System 207 Hardener 315 ml

$77.99

In stock: 13 available

Product Details

UPC: 811343010652

Brand: West System

207 Special Clear Hardener™ was developed for coating and fiberglasscloth application where an exceptionally clear, moisture-resistant,natural wood finish is desired. 207 Hardener will not blush or turncloudy in humid conditions. Thin film applications roll out and tip offsmoothly, requiring less sanding in preparation for finish coatings.

Professional and first-time builders like 207 because it is reliableand easy to use. Three coats or more can be applied in one day withoutadditional surface preparation. Fewer coats are required to fillfiberglass weave and in most cases the final coating can be sanded thefollowing day. Boats can be built faster. Builders also appreciate theexcellent fiberglass wet-out characteristics achieved with 105/207, yetit won't drain from vertical surfaces like the very slow curing,low-viscosity epoxies.

105/207 has strong physical properties, so it can be used as astructural adhesive for gluing and l aminating. It has excellentcompatibility with paints and varnishes. An ultraviolet inhibitor in 207helps provide a beautiful, long lasting finish when used with qualityUV filtering varnish. 105/207 cures clear and colorless.

Mix Ratio, Resin:Hardener 3 parts resin : 1 part hardener

Pot life at 72°F (22°C) 20 to 26 minutes

Cure to a solid state 10 to 15 hours

Cure to maximum strength 4 to 7 days

Minimum recommended temperature 60°F (16°C)

Pumps 300, 306-23 or 309-3

Save this product for later

Customer reviews

Reviews only from verified customers

No reviews yet. You can buy this product and be the first to leave a review.

West System 207 Hardener 315 ml

You May Also Like

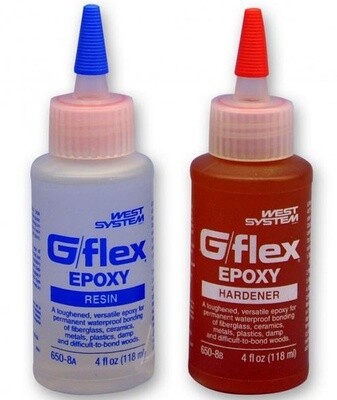

G/Flex 655 Epoxy Adhesive Repair Kit 2 quarts

G/Flex 655 Epoxy Adhesive Repair Kit 2 quarts

SKU 811343014773

$264.99

Display prices in:CAD